Que signifie votre code Code Défaut MERCEDES ?

Grace au système OBD, les

Mercedes

fabriqués après 1996 sont normalement équipés d'une prise diagnostique OBD.

Si l'ordinateur de la voiture rencontre un problème,un code d'erreur ou un code de diagnostic (DTC)

sera stocké dans la mémoire de l'ECU de la voiture.

Avec un lecteur OBD branché sur le port OBD (On-Board Diagnostics) de la voiture, vous pouvez lire la liste des codes stockés, et donc découvrir quel est le problème.

Les codes suivent une formule permettant de savoir généralement quel est le problème avant même de regarder le tableau ci-dessous.

Nous vous présentons ci-dessus une liste très complète des différents codes défauts possibles.

Si le code défaut de votre auto s'affiche au tableau de bord, vous n'aurez peut-être même pas besoin d'un lecteur OBD . il sera dans la liste .

Réparer le code défaut de votre auto, c'est potentiellement simple à faire avec vos revues et méthodes techniques.

Réparer le code défaut de votre auto, c’est potentiellement simple à faire avec nos revues et méthodes techniques

| Code | Libellé |

|---|---|

| 18AC00 | Component 'M16/6 (Throttle valve actuator)' has overtemperature |

| 18AD00 | The control deviation of the throttle valve is too high |

| 18AE00 | Teach-in of the throttle valve end stop has failed |

| 18AF00 | Component 'M16/6 (Throttle valve actuator)' sticks in the open state |

| 18B000 | Component 'M16/6 (Throttle valve actuator)' is stuck |

| 18B400 | One or more signals sent from control unit 'N118/5 (AdBlue control unit)' via the CAN bus is implausible |

| 18B400 | Fault in system AdBlue-Control unit N141 (AdBlue control unit) software fault |

| 18B500 | The power supply of the soot particulate sensor has a short circuit to ground |

| 18B600 | The boost pressure is too high during a cold start |

| 18B700 | The signal of component 'M55 (Intake port shutoff actuator motor)' is implausible |

| 18B800 | The signal of component 'NOx sensor' is implausible |

| 18B900 | The signal of component 'NOx sensor' is implausible |

| 18BA00 | The signal of component 'NOx sensor downstream of SCR catalytic converter' is implausible |

| 18BB00 | The signal of component 'NOx sensor downstream of SCR catalytic converter' is implausible |

| 18BF00 | The signal of component 'NOx sensor upstream of SCR catalytic converter' is implausible |

| 18C400 | The difference between the measured signal and the calculated signal of the NOx sensor upstream of the SCR catalytic converter is too great |

| 18C500 | The difference between the measured signal and the calculated signal of the NOx sensor downstream of the SCR catalytic converter is too great |

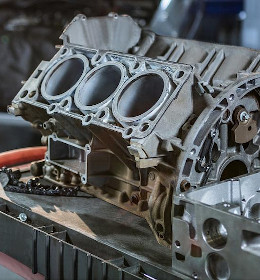

| 18C600 | The correction value for the smooth running control of cylinder 1 is outside the permissible range |

| 18C700 | The correction value for the smooth running control of cylinder 4 is outside the permissible range |

| 18C800 | The correction value for the smooth running control of cylinder 2 is outside the permissible range |

| 18C900 | The correction value for the smooth running control of cylinder 5 is outside the permissible range |

| 18CA00 | The correction value for the smooth running control of cylinder 3 is outside the permissible range |

| 18CB00 | The correction value for the smooth running control of cylinder 6 is outside the permissible range |

| 18CC00 | The signal of component 'Y85 (Exhaust gas recirculation cooler bypass switchover valve)' is implausible |

| 18CD00 | No CAN message from control module 'Airbag' or message is faulty |

| 18CE00 | The power consumption of component 'N74 (Soot particulate sensor control unit)' is too high |

| 18CF00 | Component 'N74 (Soot particulate sensor control unit)' has an internal fault |

| 18D200 | The measured NOx concentration is implausible |

| 18D500 | The rail pressure is too low during engine start |

| 18DB00 | Oxygen sensor 1 (cylinder bank 1) has a delayed reaction |

| 18DD00 | Oxygen sensor 1 (cylinder bank 1) has a delayed reaction |

| 18F300 | The heater of component 'G3/2 (Oxygen sensor upstream of catalytic converter)' has a malfunction |

| 18F600 | The position sensor for the selector lever has a malfunction |

| 18F700 | The position sensor for the selector lever has a malfunction |

| 1B0000 | Component 'Y621 (Exhaust gas recirculation controller)' does not close. |

| 1B0001 | Component 'Y621 (Exhaust gas recirculation controller)' does not open. |

| 1B0003 | The signal voltage of component 'Y621 (Exhaust gas recirculation controller)' is too high. |

| 1B0004 | The signal voltage of component 'Y621 (Exhaust gas recirculation controller)' is too low. |

| 1B0007 | Component 'Y621 (Exhaust gas recirculation controller)' has a mechanical fault. |

| 1B000C | Component 'Exhaust gas recirculation valve' is frozen. |

| 1C4E00 | The differential lock on the rear axle has a malfunction |

| 2002-001 | The signal from component N129 (Starter generator squib) is faulty; Short circuit to positive |

| 2002-002 | The signal from component N129 (Starter generator squib) is faulty; Short circuit to ground |

| 2002-004 | The signal from component N129 (Starter generator squib) is faulty; Open circuit in wiring |

| 20-040000 | The Keyless-Go control unit (N69/5) crashes |

| 2004-008 | Monitoring of thermostat |

| 2008-001 | Rail pressure sensor offset test. The signal voltage is too high. |

| 2008-002 | Rail pressure sensor offset test. The signal voltage is too low. |

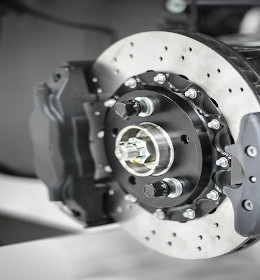

| 2009-001 | The signal voltage of sensor 1 of component B64/1 (Brake vacuum sensor); is too high |

| 2009-002 | The signal voltage of sensor 1 of component B64/1 (Brake vacuum sensor) is too low |

| 2009-002 | Water in the fuel filter |

| 2009-004 | Water level sensor; Water in the fuel filter |

| 200A | B2/13 (Hot film mass air flow sensor)- Short circuit to positive. |

| 200A-001 | The signal voltage of sensor 2 of component B64/1 (Brake vacuum sensor) is too high |

| 200A-002 | The signal voltage of sensor 2 of component B64/1 (Brake vacuum sensor) is too low |

| 200B | L5/12 (Crankshaft sensor)- Signal implausible. |

| 200B | Signal '1' from component 'B64/1 (Brake vacuum sensor)' is implausible |

| 200B | The signal from component 'B6/1 (Camshaft Hall sensor)' is faulty |

| 200C | Control unit Continuously variable automatic transmission (CVT) is defective |

| 200C | L5/12 (Crankshaft sensor)- No signal. |

| 200C | Signal '2' from component 'B64/1 (Brake vacuum sensor)' is implausible |

| 200C | The assignment of signals from the crankshaft and camshaft is faulty |

| 200D | Check component 'L5 (Crankshaft position sensor)' |

| 200D | Implausible signals from component B64/1 (Brake vacuum sensor) |

| 200F | Fault in communication with component N129 (Starter generator squib) or there is an open circuit |

| 200F | Y62/27 (Cylinder 1 fuel injection valve)- Control cable has Short circuit to positive |

| 2010-001 | Check component B2/5 (Hot film mass air flow sensor)Offset drift; Value is above limit |

| 2010-001 | Component B101 (Mass air flow sensor) is faulty; Measuring range exceeded |

| 2010-002 | Check component B2/5 (Hot film mass air flow sensor)Offset drift; Value is below limit |

| 2010-002 | Component B101 (Mass air flow sensor) is faulty; Measuring range exceeded |

| 2011-001 | B101 (Mass air flow sensor) Measuring range exceeded |

| 2011-001 | Check component B2/5 (Hot film mass air flow sensor)Sensitivity drift; Air mass ratio for calculated quantity (top) |

| 2011-002 | B101 (Mass air flow sensor) Readout below range |

| 2011-002 | Check component B2/5 (Hot film mass air flow sensor)Sensitivity drift; Air mass ratio for calculated quantity (bottom) |

| 2012-008 | Check component B11/4 (Coolant temperature sensor); The dynamic test was not plausible |

| 2012-008 | The signal from component B16 (Coolant temperature sensor) is faulty |

| 2013-001 | The signal from component Outside air temperature sensor is faulty; The signal voltage is too high |

| 2013-002 | The signal from component Outside air temperature sensor is faulty; The signal voltage is too low |

| 2013-004 | The signal from component Outside air temperature sensor is faulty; Fault from instrument cluster over CAN |

| 2014-001 | Check component B40 (Oil sensor (oil level, temperature and quality)); Value is above limit |

| 2014-001 | The signal from component B110 (Engine oil sensor) is faulty; The signal voltage is too high |

| 2014-002 | Check component B40 (Oil sensor (oil level, temperature and quality)); Value is below limit |

| 2014-002 | The signal from component B110 (Engine oil sensor) is faulty; The signal voltage is too low |

| 2014-004 | Check component B40 (Oil sensor (oil level, temperature and quality)); Oil temperature is implausible |

| 2014-004 | The signal from component B110 (Engine oil sensor) is faulty; Oil temperature is implausible |

| 2014-008 | Check component B40 (Oil sensor (oil level, temperature and quality)); Plausibility |

| 2014-008 | The signal from component B110 (Engine oil sensor) is faulty; Signal implausible |

| 2015-001 | Rail pressure monitoring. The maximum fuel flow quantity was exceeded |

| 2016-001 | Rail pressure monitoring. Fuel flow was below the specified minimum quantity. |

| 2016-002 | Rail pressure monitoring via volume control valve; The pressure reduction during deceleration is implausible |

| 2016-004 | Rail pressure monitoring via volume control valve; Standard deviation in deceleration mode |

| 2016-008 | Rail pressure monitoring via volume control valve; Standard deviation in idle |

| 2016-01 | Fuel rail/system pressure too high |

| 2017-001 | Rail pressure monitoring. The rail pressure is too low |

| 2017-002 | Rail pressure monitoring via volume control valve; The rail pressure is too low |

| 2018-001 | Rail pressure monitoring. The rail pressure is too high. |

| 2019-001 | Rail pressure monitoring. The maximum pressure has been exceeded. |

| 2019-002 | Rail pressure monitoring. The rail pressure is too low |

| 201A | Component 'B5/1 (Boost pressure sensor)' has an open circuit or short circuit to positive |

| 201A | Random/multiple cylinder misfire detected |

DEFINISSEZ VOTRE MARQUE POUR ACCEDER A VOS CODES DEFAUTS

-

Revue technique RTA

Revue Technique Automobile

La revue technique de référence depuis 1946. La RTA est une revue papier pour tous publics, qui vous permet d'effectuer les petites et les grosses réparations

Voir le descriptif

Voir le descriptif

-

Entretien courant MTA

Méthode Technique Automobile

La MTA est issue de nos outils destinés aux pros de l'auto. Ces méthodes en ligne permettent d'effectuer les opérations de maintenances de votre auto (filtres, courroies, etc.)

Voir le descriptif

Voir le descriptif

-

Toutes réparations MTAx

Méthode Technique Automobile Expert

La MTA expert est un outil en ligne destiné aux experts en mécanique et en carrosserie, pour effectuer tous types de réparations sur une voiture.

Voir le descriptif

Voir le descriptif